A pulley is born

Blank round of 6061-T6 aluminum barstock:

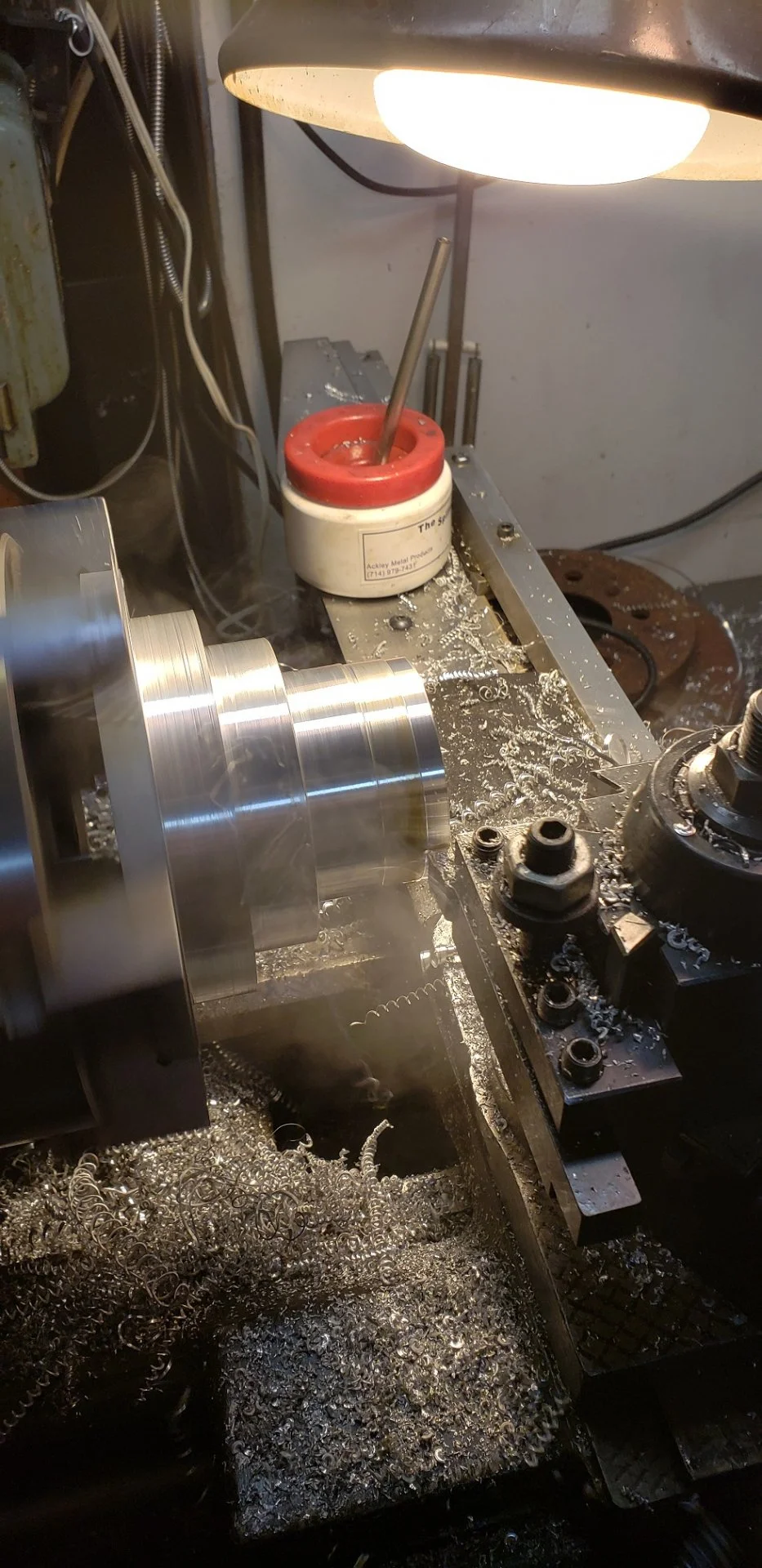

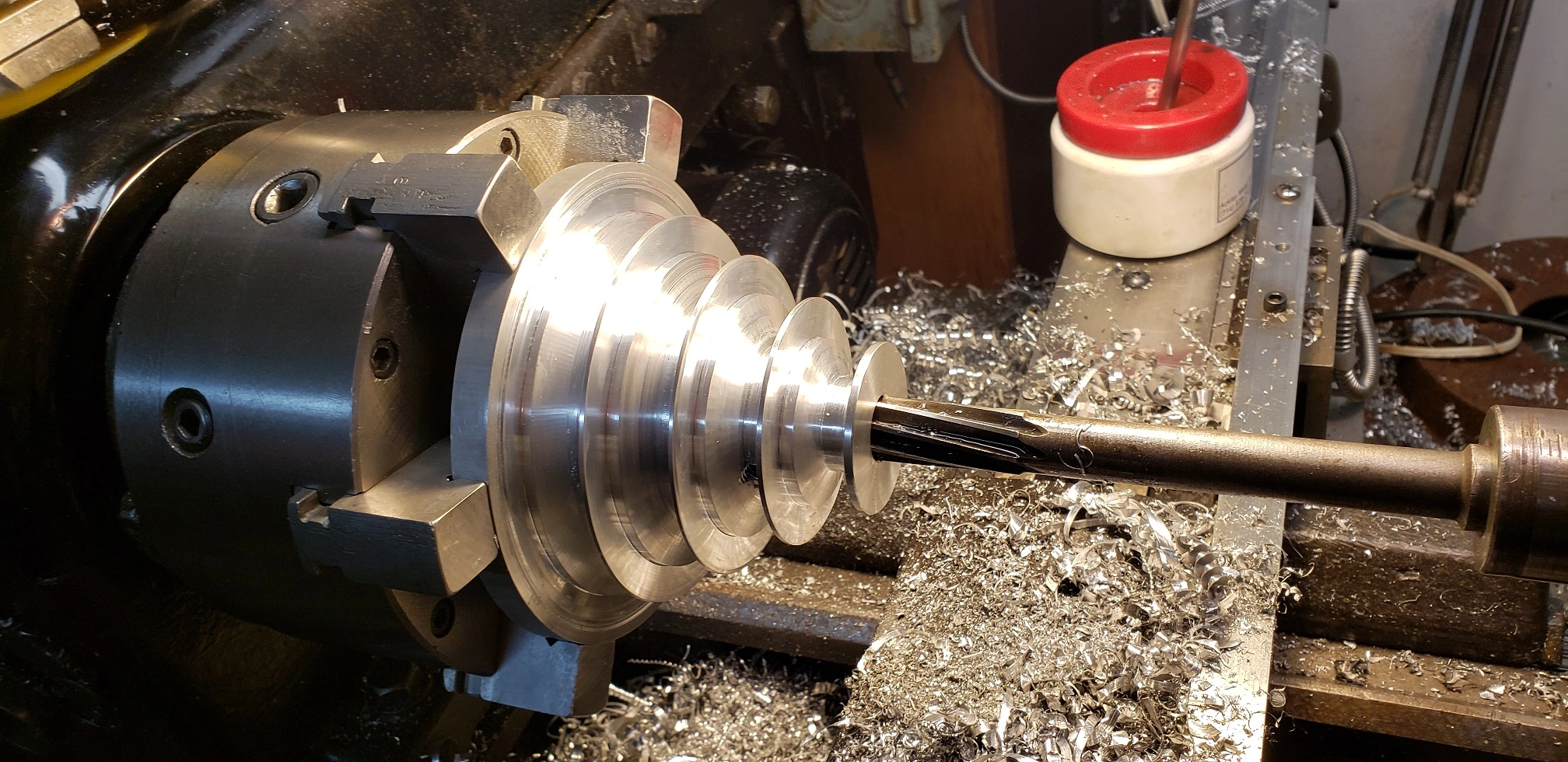

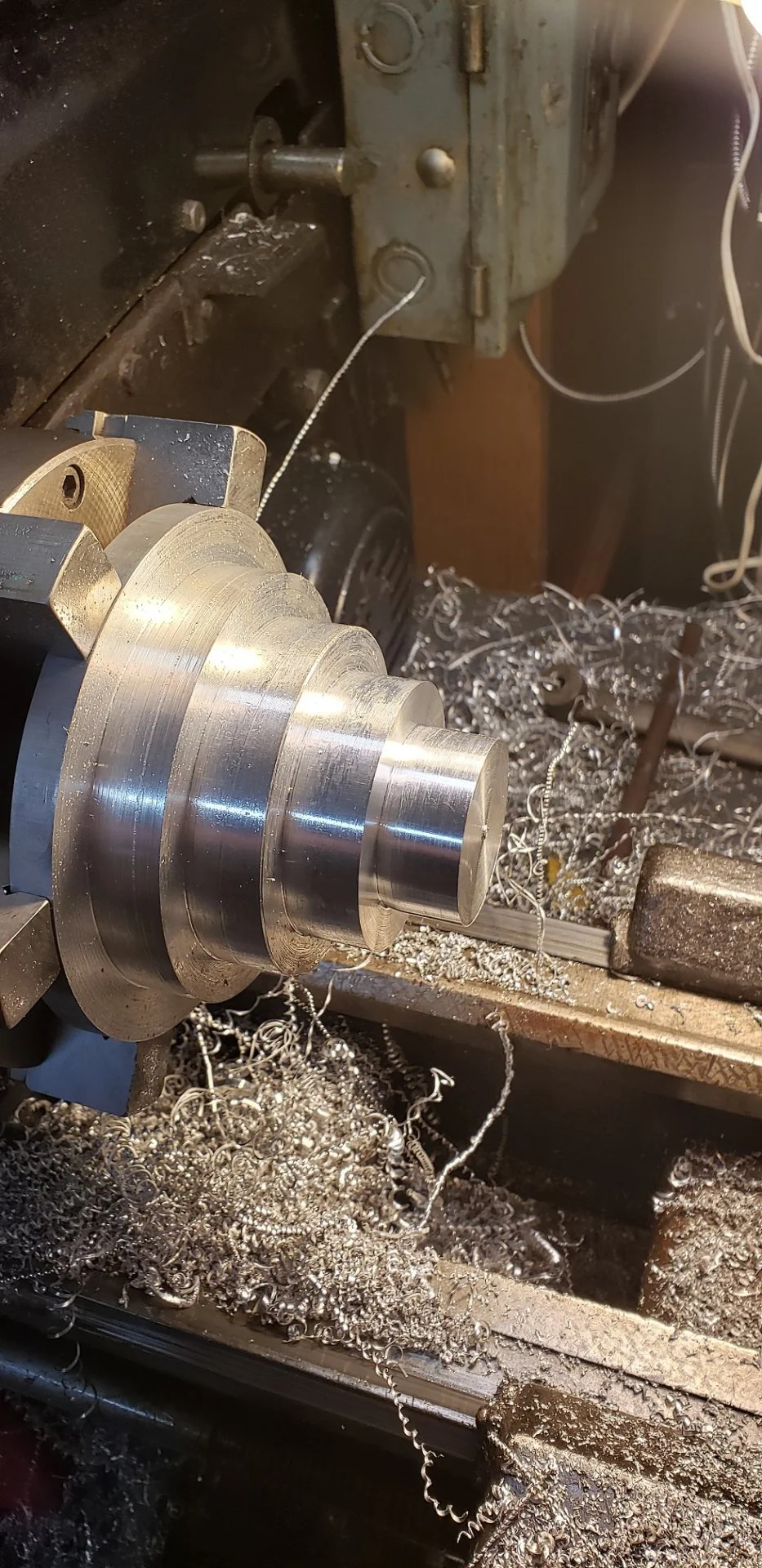

Rough OD cuts to size the blank:

Yes, that is smoke coming off the cutting oil.

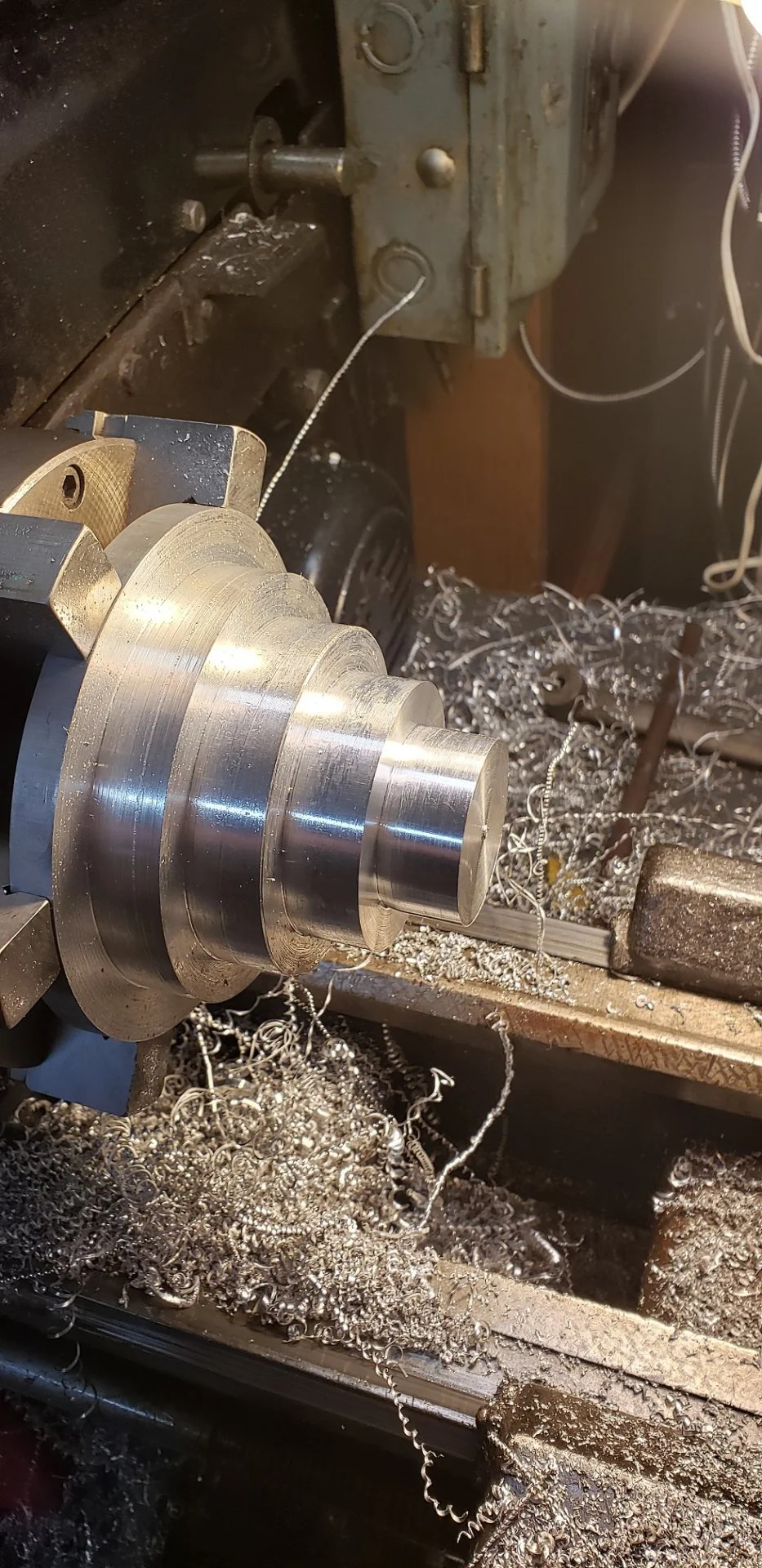

Rough machined outside diameters:

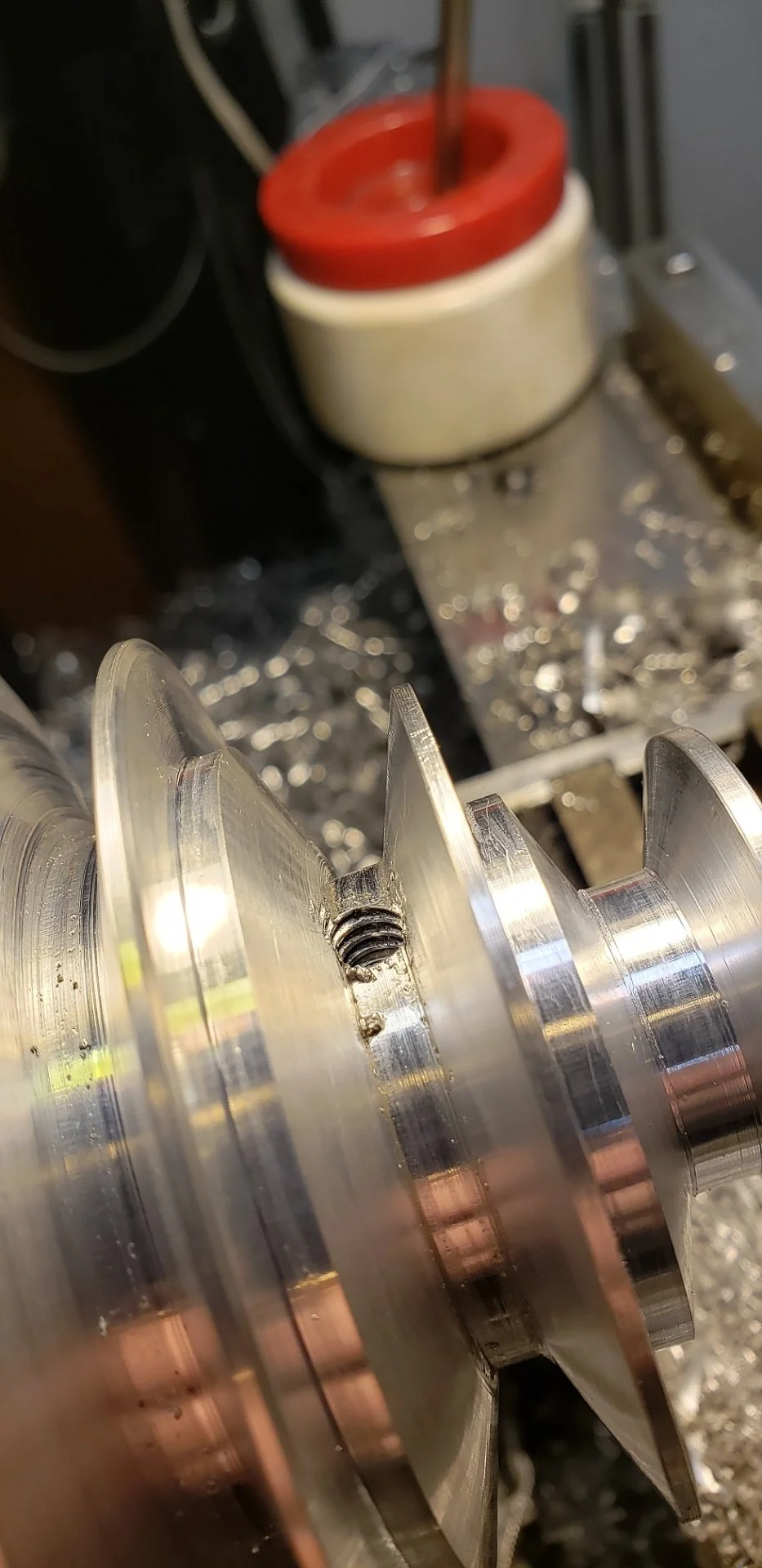

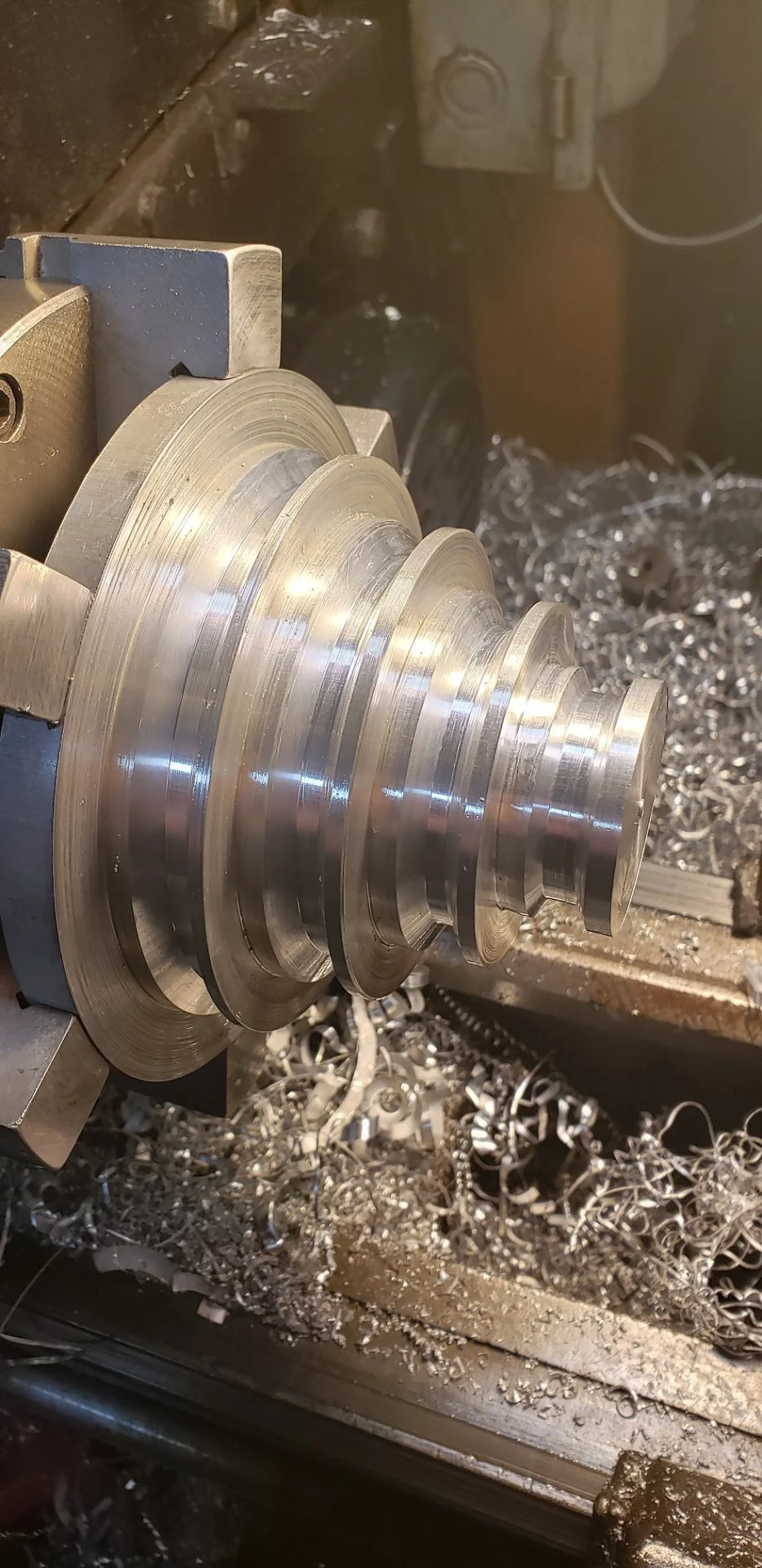

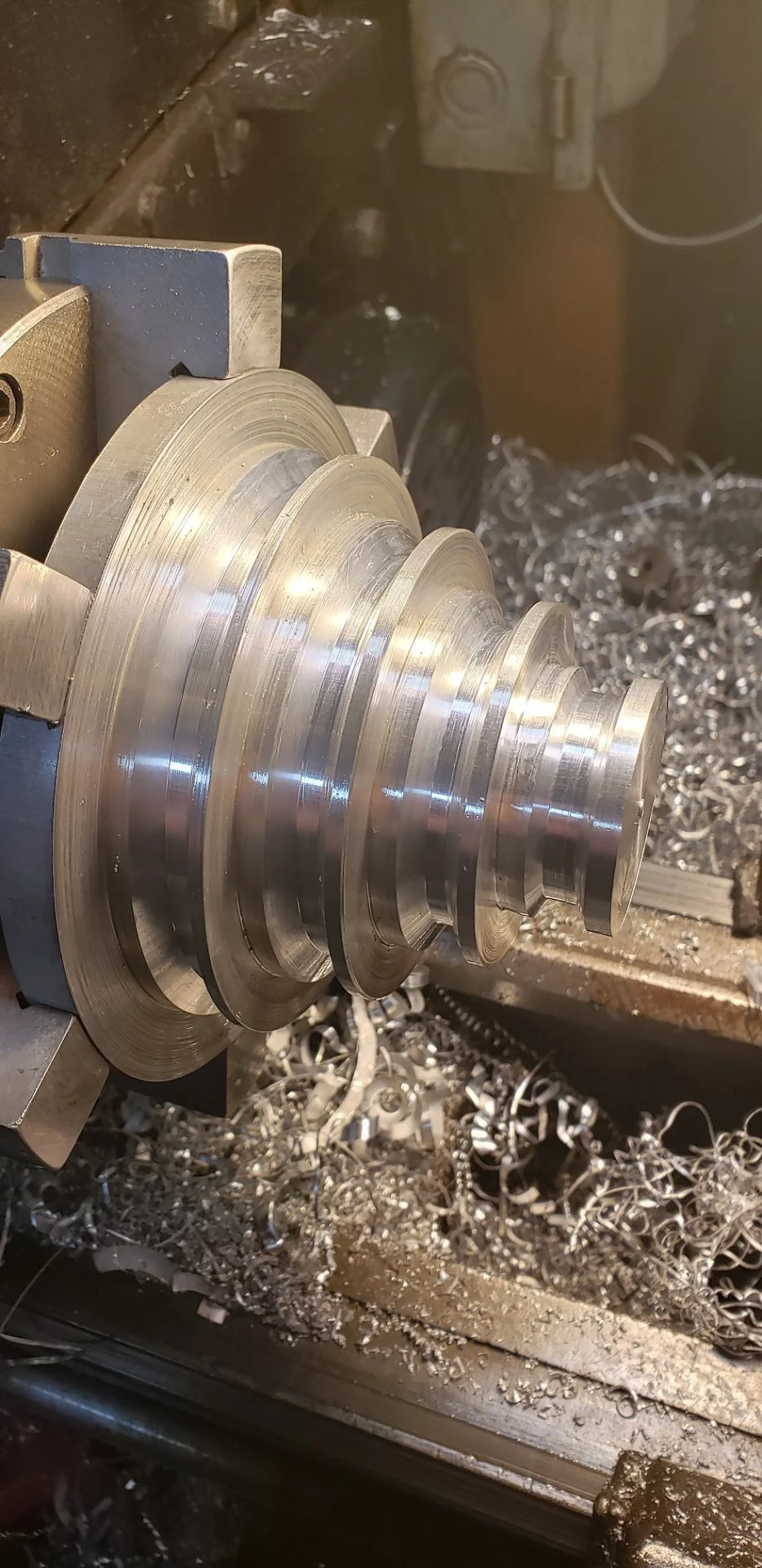

Rough cut grooves:

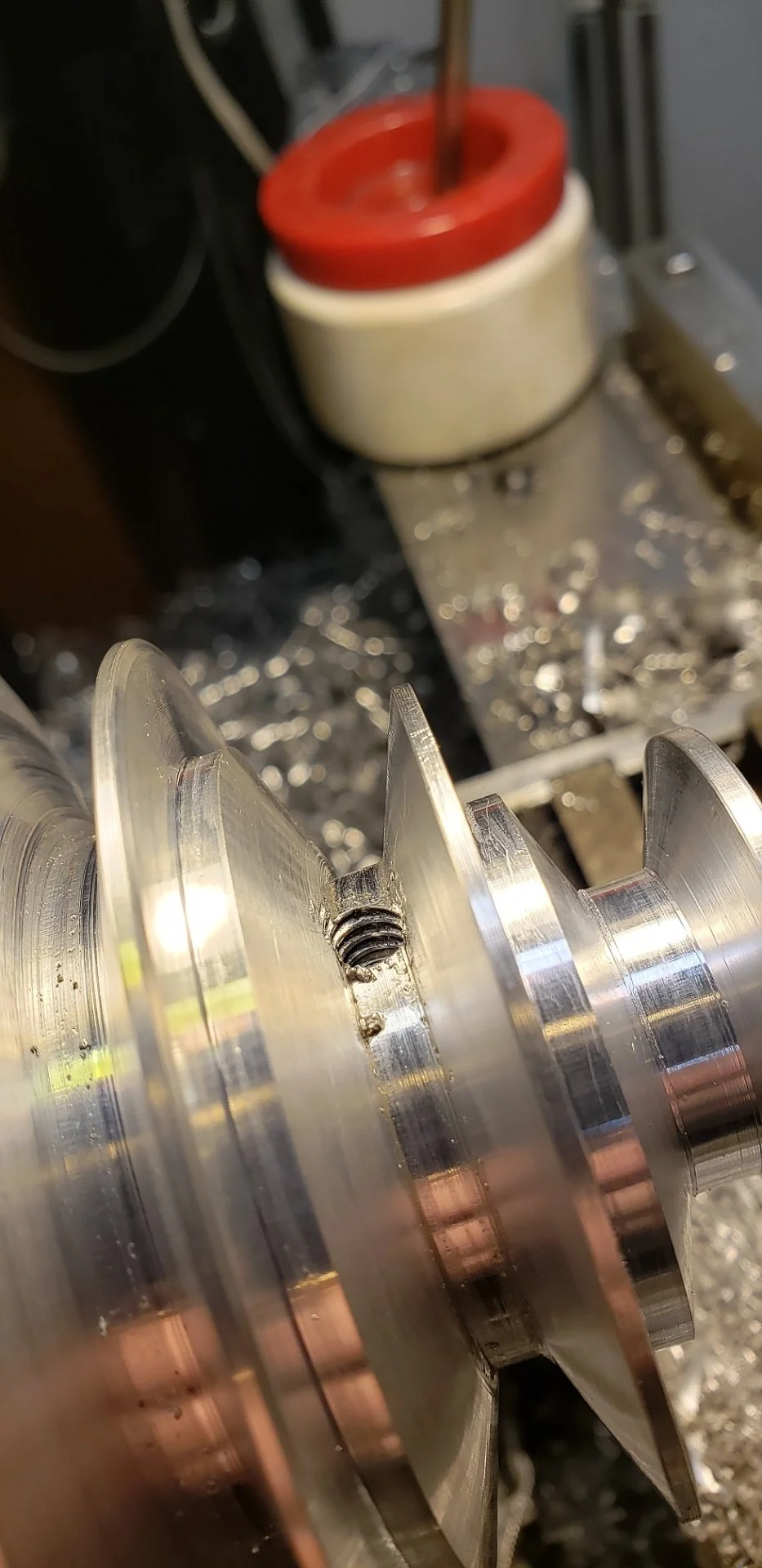

Semi finished grooves:

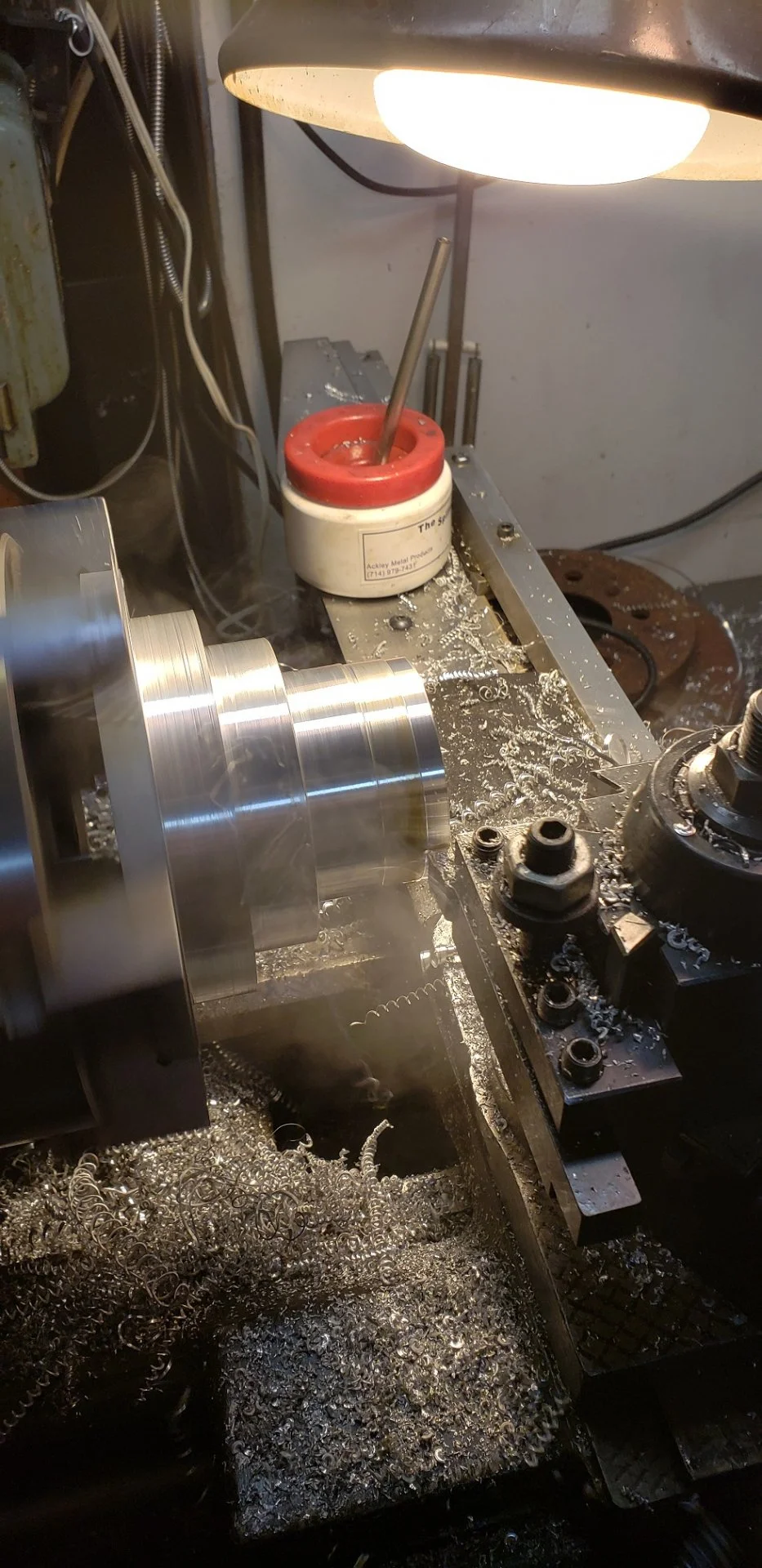

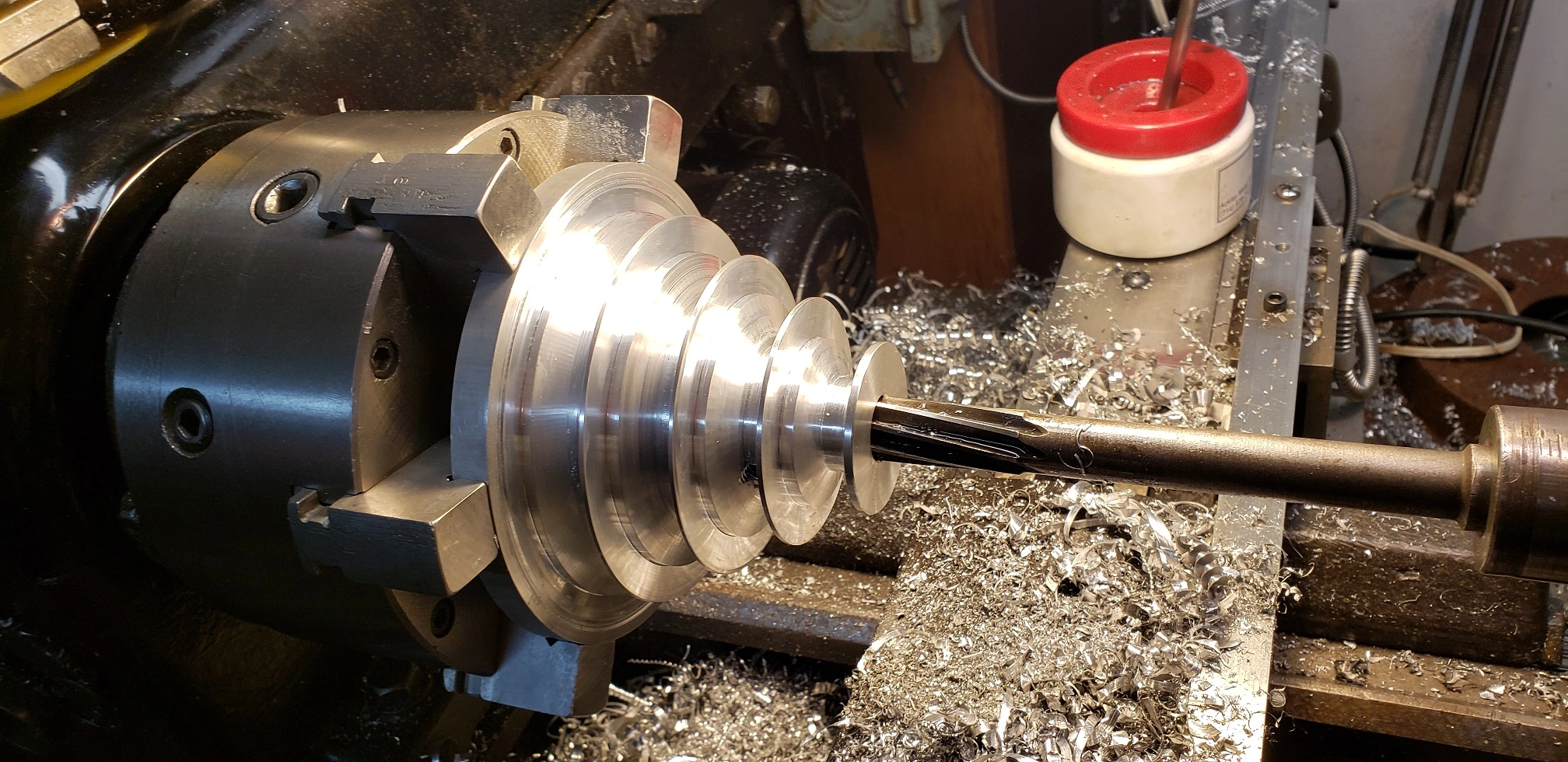

After a thru hole was drilled, it was reamed to final size in order to make an accurate fit to a motor shaft:

Next, a cross hole was drilled for the set screw:

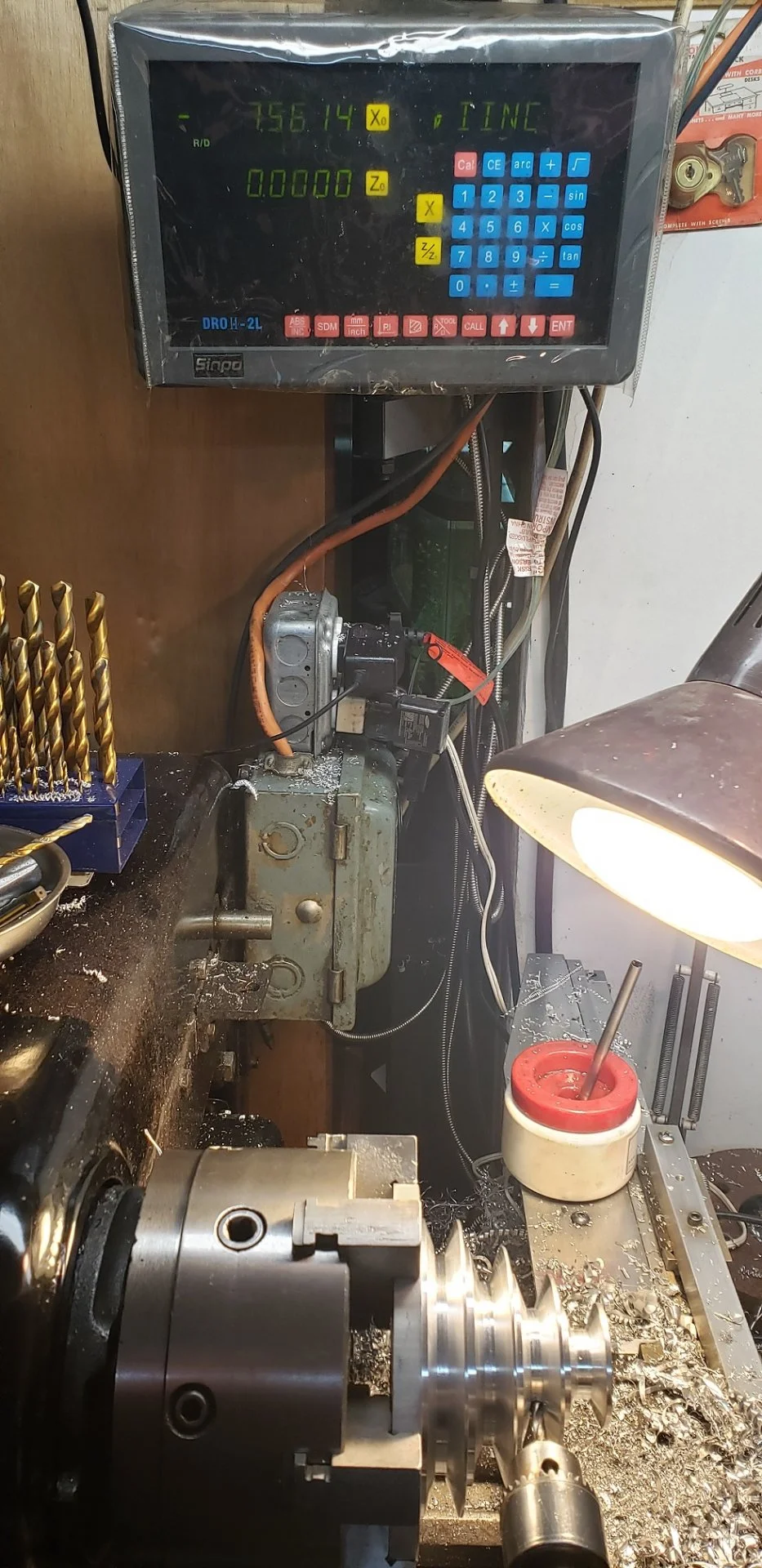

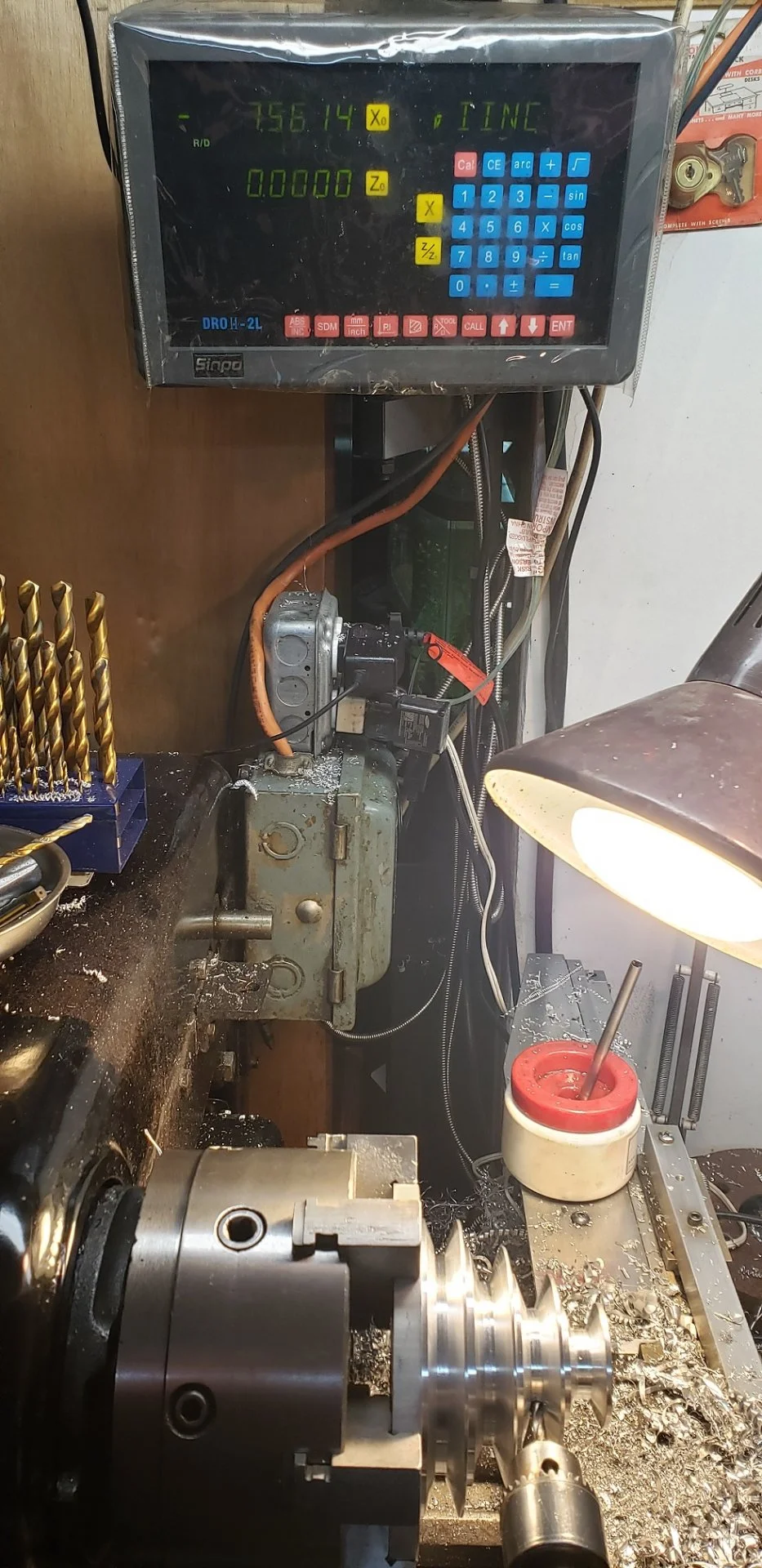

My digital positioning readout pictured above was used to center the hole in the bore and pulley groove:

After drilling, the threads were tapped for the set screw that fixes the pulley to the motor shaft:

Blank round of 6061-T6 aluminum barstock:

Rough OD cuts to size the blank:

Yes, that is smoke coming off the cutting oil.

Rough machined outside diameters:

Rough cut grooves:

Semi finished grooves:

After a thru hole was drilled, it was reamed to final size in order to make an accurate fit to a motor shaft:

Next, a cross hole was drilled for the set screw:

My digital positioning readout pictured above was used to center the hole in the bore and pulley groove:

After drilling, the threads were tapped for the set screw that fixes the pulley to the motor shaft: