I will drill holes in the right places.I like the efgorts on the acles alot , pretty creative but do you have to mold those

housing around the actual axle shafts .

-

Feeling isolated? You're not alone.

Join 20,000+ people who understand exactly how your day went. Whether you're newly diagnosed, self-identified, or supporting someone you love – this is a space where you don't have to explain yourself.

Join the Conversation → It's free, anonymous, and supportive.

As a member, you'll get:

- A community that actually gets it – no judgment, no explanations needed

- Private forums for sensitive topics (hidden from search engines)

- Real-time chat with others who share your experiences

- Your own blog to document your journey

You've found your people. Create your free account

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Talking About Trains...

- Thread starter Captain Caveman

- Start date

I have some drill bits I can hardly see. 0.3mm.Thats a pretty small drill .

0.3mm is also the smallest size my drill takes. Dare not use that size without a drill stand though and can hardly see it myself without using my reading glasses! Some of the smallest drill bits in my drill set could dissapear and I may not even notice!

I have rarely used the smallest ones as I mostly use about 0.75mm or larger depending on what I am drilling, and mostly I don't look at the mm size. I just say "That will do", pick it out and use it in the drill!

Is only if assembling kits that specify a certain drill size that I will look at the drill measurements, and even then it can be a guess in the hope I have the right one. (The measurements do not quite line up with the slots for the drill bits on my drill case. I have a spare set as well and it is the same with that set).

I have rarely used the smallest ones as I mostly use about 0.75mm or larger depending on what I am drilling, and mostly I don't look at the mm size. I just say "That will do", pick it out and use it in the drill!

Is only if assembling kits that specify a certain drill size that I will look at the drill measurements, and even then it can be a guess in the hope I have the right one. (The measurements do not quite line up with the slots for the drill bits on my drill case. I have a spare set as well and it is the same with that set).

Last edited:

And you. do this work by eye ..???? Yes I understand about the drill stand . of course .

I keep a small drill press, with adaptor for tiny bits , and a set of dental grinding bits .

Probably not made of the best steel though. but the fine holes and drill bits, often will conciously try to avoid getting to those situations , Especially if alignment is a issue.

I keep a small drill press, with adaptor for tiny bits , and a set of dental grinding bits .

Probably not made of the best steel though. but the fine holes and drill bits, often will conciously try to avoid getting to those situations , Especially if alignment is a issue.

yes,, looks authentic ,, almost expect the chimeny to start smoking .

I wonder where I have seen these before?

Attachments

Lolzzz ... very Nice ..all I had to do was stand up from the couch, and look on the highest shelf in the living room . right above the couch . They have display spot up there . Love the appearance of authenticity . On that same shelf is a large Oak wood triangle ,the folded flag inside is, that flag that every veterans family recieves upon the death of a veteran of that family passes on, USA flags are traditionally always folded in such a way that the flag forms a triangle to display or in storage . Recognising the service of that Soldier did for their country. The train sits on that shelf in proud display, Of a Friendship

that someone has had with a Soldier, whom has not passed but was a soldier herself and the Wife of that same soldier who passed .Whose flag is on display . If and when that Train and tender comes down from that shelf . It will be for And new set of tracks for it to ride on . There are only a few such items in this house that get to sit on that shelf here . All collectables .Of one sort or another .

that someone has had with a Soldier, whom has not passed but was a soldier herself and the Wife of that same soldier who passed .Whose flag is on display . If and when that Train and tender comes down from that shelf . It will be for And new set of tracks for it to ride on . There are only a few such items in this house that get to sit on that shelf here . All collectables .Of one sort or another .

Lolzzz ... very Nice ..all I had to do was stand up from the couch, and look on the highest shelf in the living room . right above the couch . They have display spot up there . Love the appearance of authenticity . On that same shelf is a large Oak wood triangle ,the folded flag inside is, that flag that every veterans family recieves upon the death of a veteran of that family passes on, USA flags are traditionally always folded in such a way that the flag forms a triangle to display or in storage . Recognising the service of that Soldier did for their country. The train sits on that shelf in proud display, Of a Friendship

that someone has had with a Soldier, whom has not passed but was a soldier herself and the Wife of that same soldier who passed .Whose flag is on display . If and when that Train and tender comes down from that shelf . It will be for And new set of tracks for it to ride on . There are only a few such items in this house that get to sit on that shelf here . All collectables .Of one sort or another .

Where does the Gnomy sit?

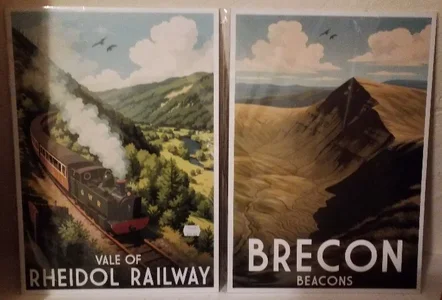

Recently bought two card replicas of past enamel posters. They may be half or quarter sized, and they were not cheap, but I loved them (And love them) so much I purchased them, as they are ace!

I can get so much out of pictures! Sometimes more than words!

I can get so much out of pictures! Sometimes more than words!

Attachments

It was freshly painted.

Brecon Beacons are a mountain range in South Wales. The largest pointy one is called Pen-Y-Fan where I spent the night up there in my youth.

Also when I was younger I went on the Vale Of Rheidol railway which is quite a spectacular railway!

Brecon Beacons are a mountain range in South Wales. The largest pointy one is called Pen-Y-Fan where I spent the night up there in my youth.

Also when I was younger I went on the Vale Of Rheidol railway which is quite a spectacular railway!

Last edited:

Sounds lovely ..wish , I had a chance to see those things . must of been a great camping trip. Still that Loco looked good, factory fresh appearance

Maybe one day you can if you visit Wales one day with your other half? Maybe Pen-Y-Fan would be a bit too much, but the trains in Wales will be quite an adventure!

Just to add, though these days it can be silly prices to park and it is app only from what I understand so I can no longer park there, but in North Wales a train goes right up to near the top of the tallest mountain in Wales. You can see this on the internet onplaces like YouTube etc.

Thank You, It is now the first time you have ever offered a invite to see Wales, my Parents families home country . It would take alot of preparations, and hopefully we might survive the airports. And the countryside , maybe lovely , but am sure the Railway would be, Is this a narrow guage railway you write about ?

Thank You, It is now the first time you have ever offered a invite to see Wales, my Parents families home country . It would take alot of preparations, and hopefully we might survive the airports. And the countryside , maybe lovely , but am sure the Railway would be, Is this a narrow guage railway you write about ?

Yes. We have several narrow gauge railways in Wales. I can think of ten NG preserved railways as I write. Actually eleven along with a large number of castles, beaches, hills and mountains and other interesting things!

Last edited:

Share:

New Threads

-

How to appeal to neurodivergent women online?

- Started by BrianWV39

- Replies: 0

-

Lou Laurinen (formerly known as Luca) - its her wedding day on Sunday

- Started by Alexej

- Replies: 7

-

-

-

Trying to find potential dates on dating apps and the internet only.

- Started by BrianWV39

- Replies: 8

-

-

It’s over I’m d I f f e r e n T and so r u

- Started by AutismSupremacist

- Replies: 21

-

-

-